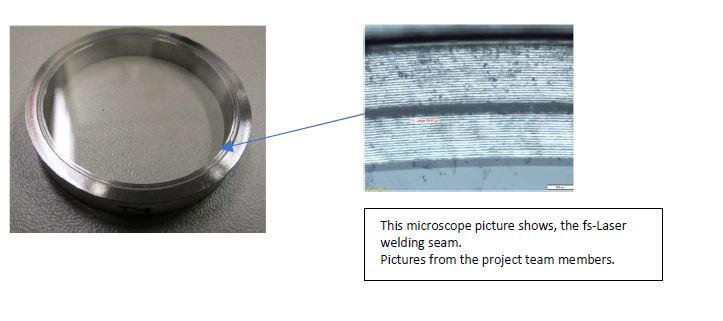

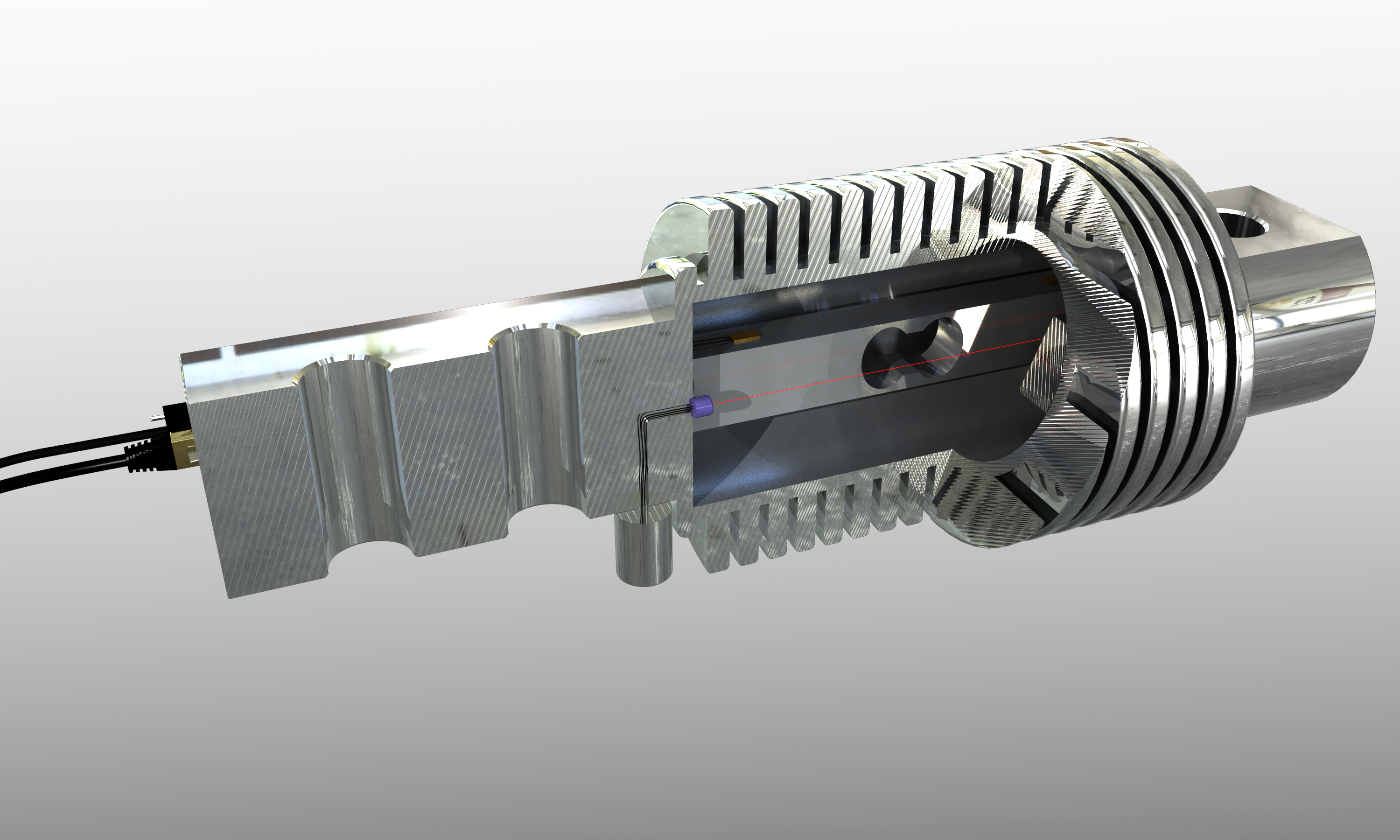

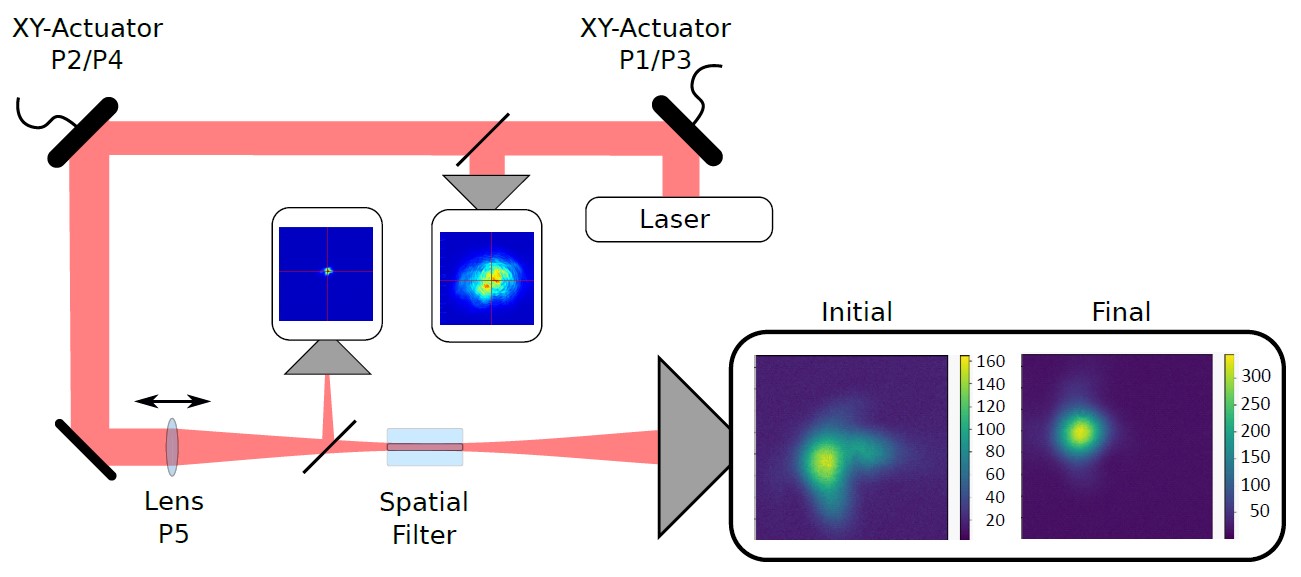

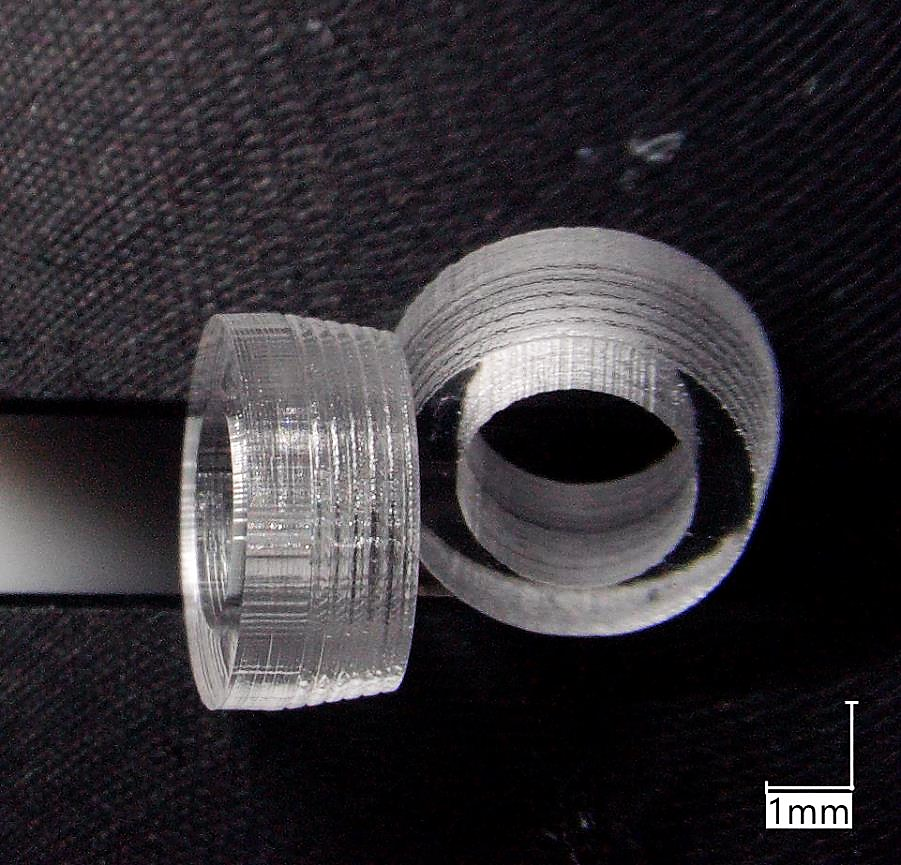

The manufacturing of water jet nozzles is manually intensive process, which increases costs, lead-times, quality control and validation needs and inventories. We explore new manufacturing technologies for the precision manufacturing of water nozzles suitable for the water jet guided laser cutting technology. The technologies selected are suitable for batch manufacturing with repeatable precision and short lead times. Thus, the supply chain can be simplified, the quality increased and the costs decreased.

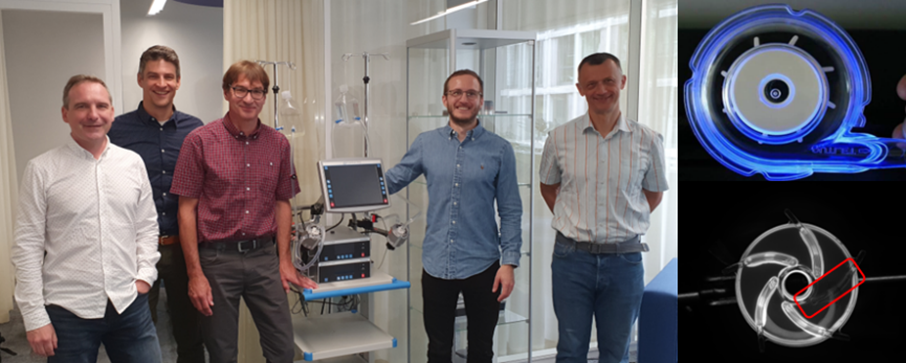

The project partners include GFD (Diamaze) for the accurate processing of lab grown diamond, Class4Laser (now Sabato Lasertec) for the femto-second laser pre and post-processing of diamond orifices, JFB for the accurate turning of metal bodies, and Synova for their competency in micro-assembly and as an end-user of the products for the water jet guided laser systems.