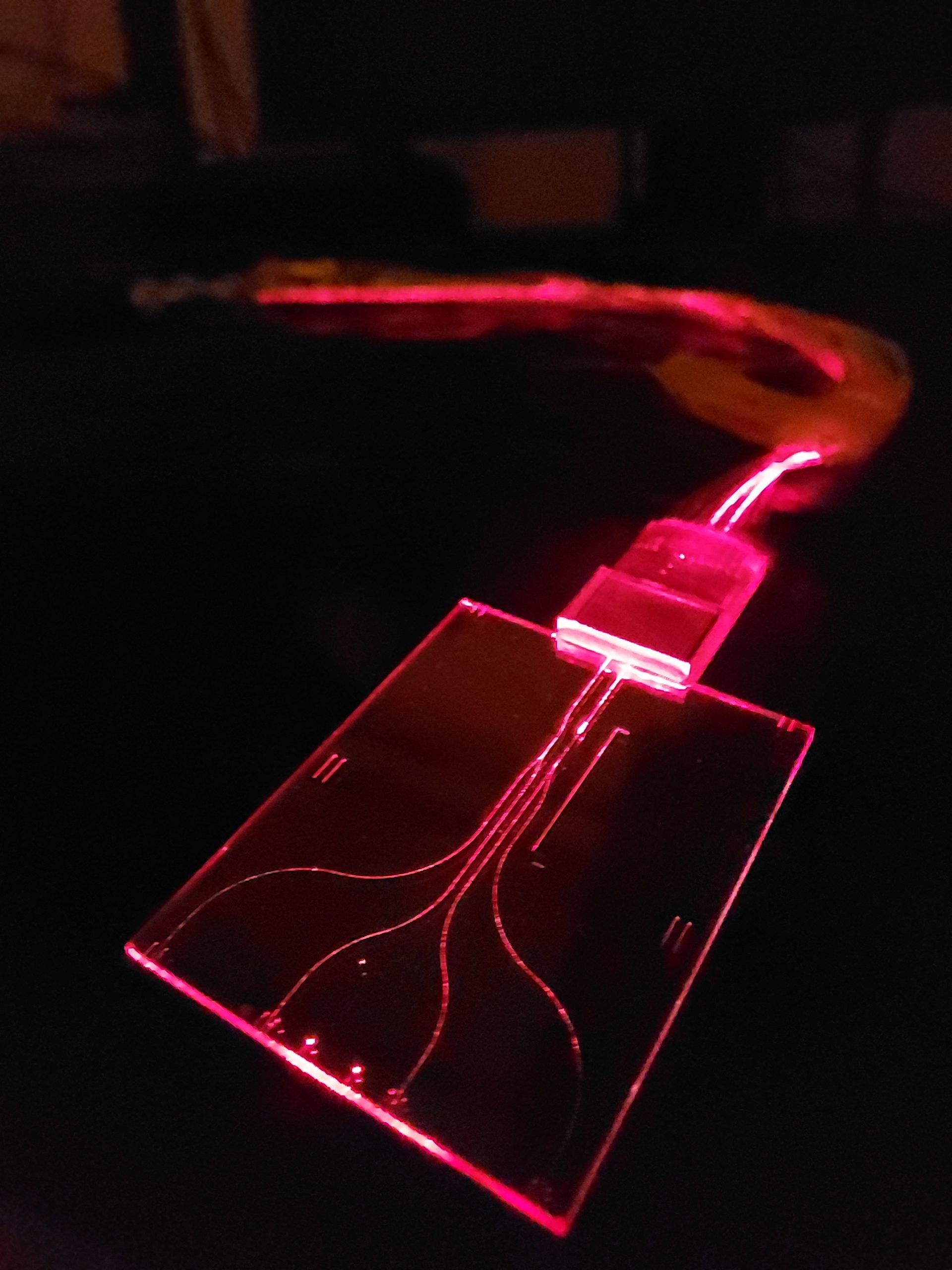

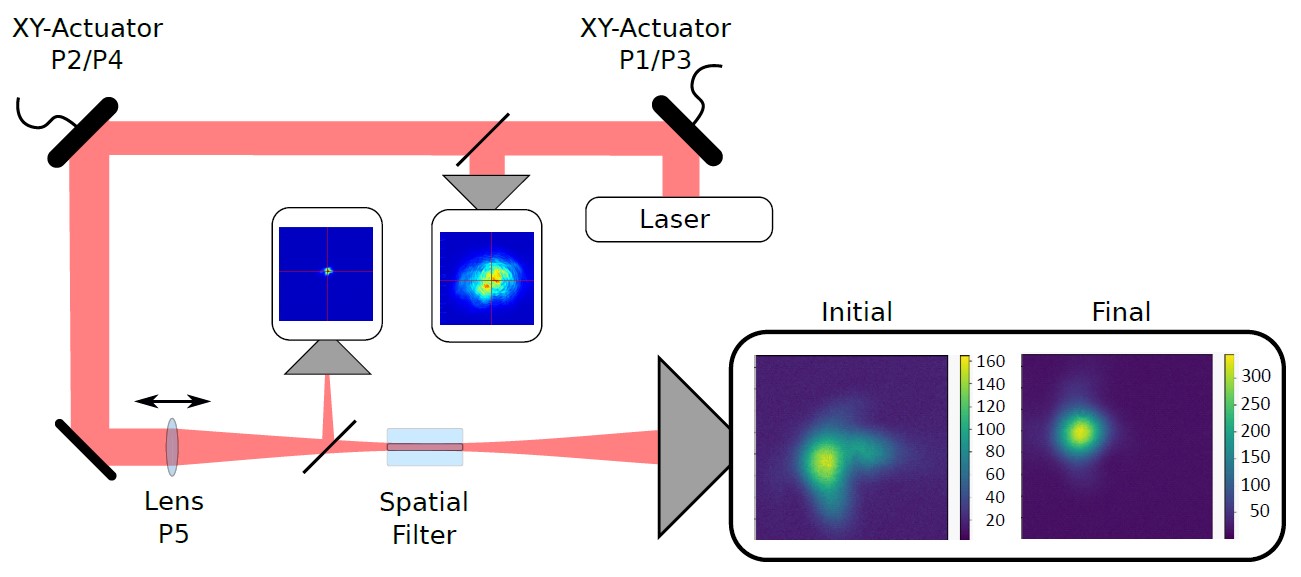

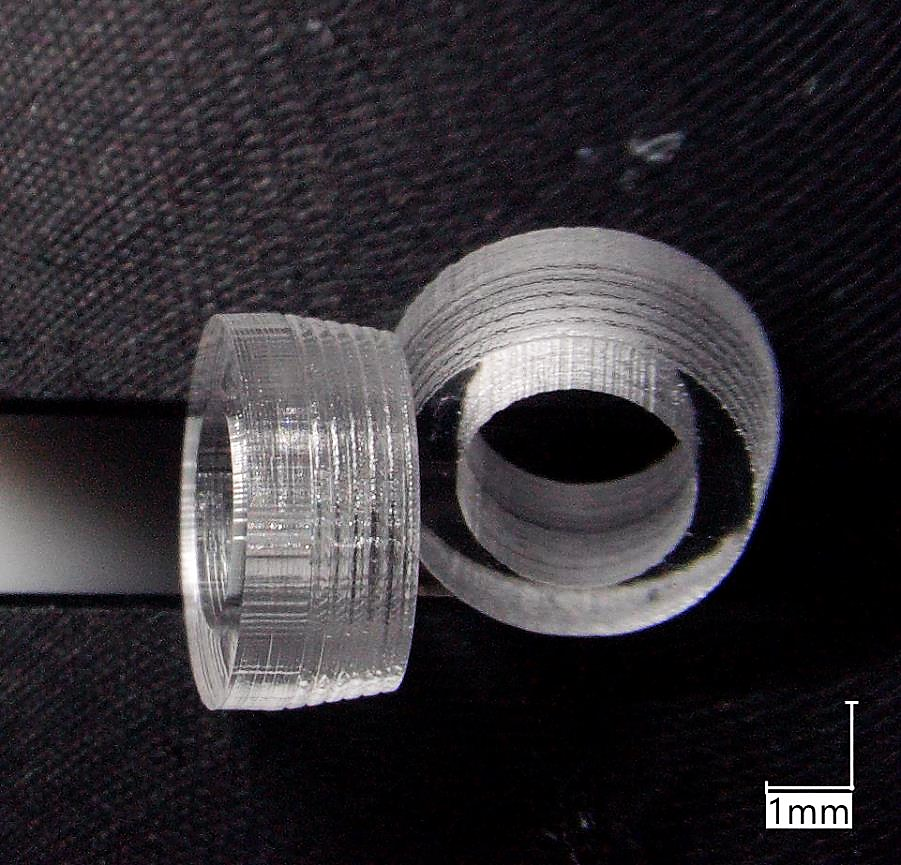

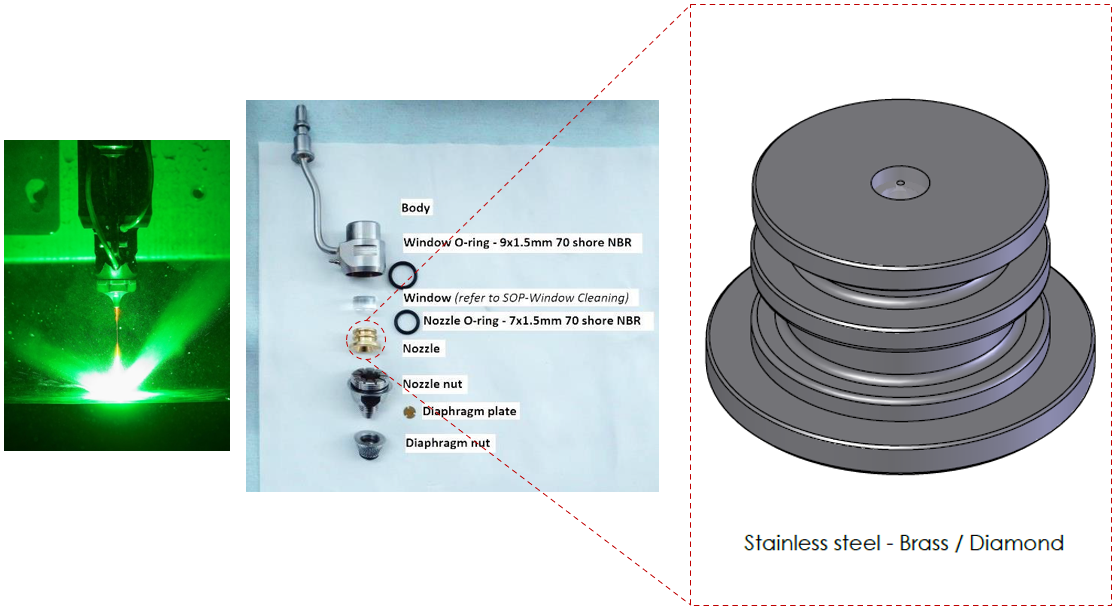

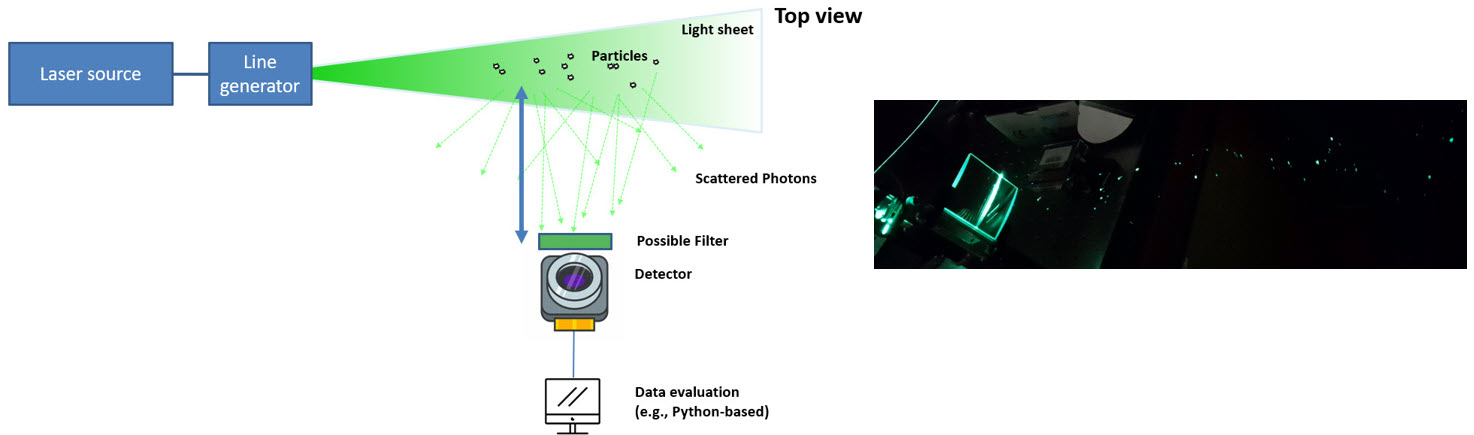

The innovative and disruptive idea is to combine the energy application of US-welding and the very local energy delivery of fs-Laser to exactly the spot where the application needs this bonding between glass-metal. The ultrasonic mechanical wave shall make the assembly possible between glass component and metallic part by improving the performance and success rate of laser welding. It will help to join the “un-joinable” metal-glass.

The advantages of this technology are:

– Applicable to Microprocessing and hence automated process assembly possible

– No heating of the work pieces

– No gluing and hence no curing time needed and no outgasing

– No polymers in the assembly process and in the joint

– Hermeticity achievable is much higher than any other assembly method

– Flat assembly, hence tools from the semicon/automation industry can be used and

integrated in the production/assembly line.

– Very short pace of process steps, hence applicable for high volume production and

can be parallelised.

The targeted applications :

The targeted applications that will profit massively from this quantum leap of hybrid microprocessing assembly technology are the following:

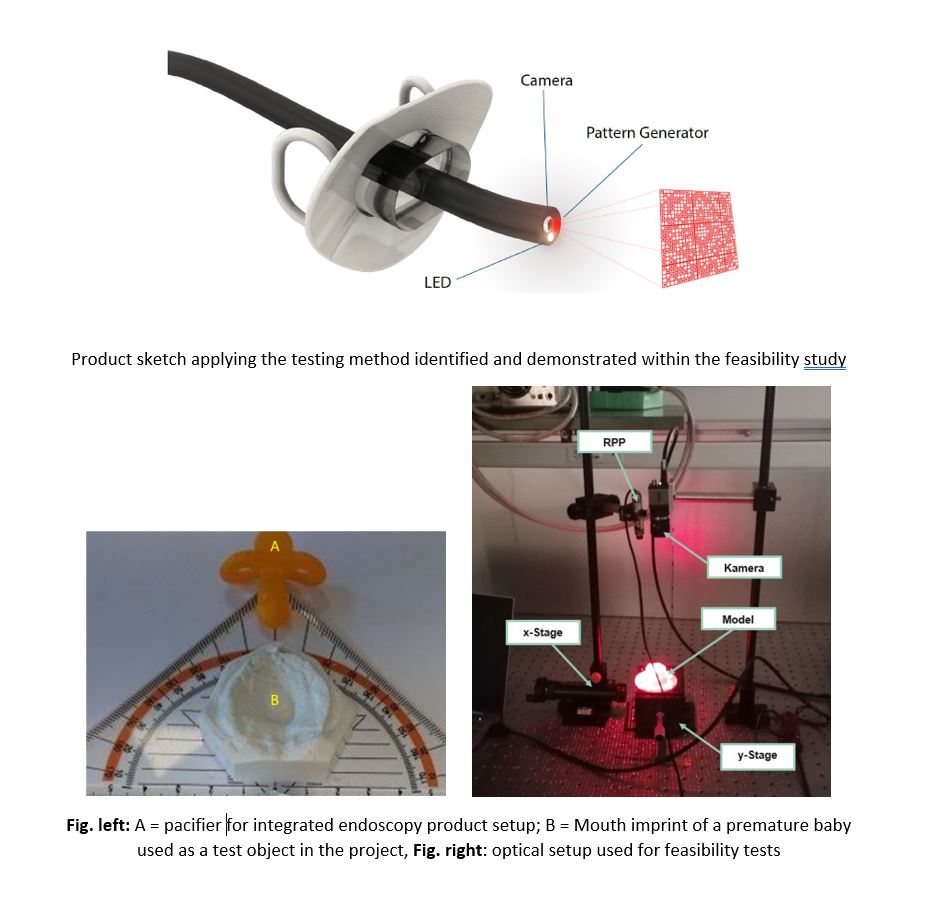

– Medical devices assembly including Type III implants

– Electronic (hermetic) packaging of photonic devices (PIC, Lidar, CCD, etc.)

– Watch assembly of watch crystal to the bezel without mechanical pressing of

polymer seals and high hermeticity

For the first two applications potential clients are awaiting with impassion the results and the patents are applied.

Project Partners:

Yalosys AG

Yalosys is doing the fs-Laser welding.

Yalosys is bringing its deep know-how on leak testing by carrying out these tests.

Yalosys is manufacturing the glass side of the samples for testing.

AAA Assemblage Acoustique Azau

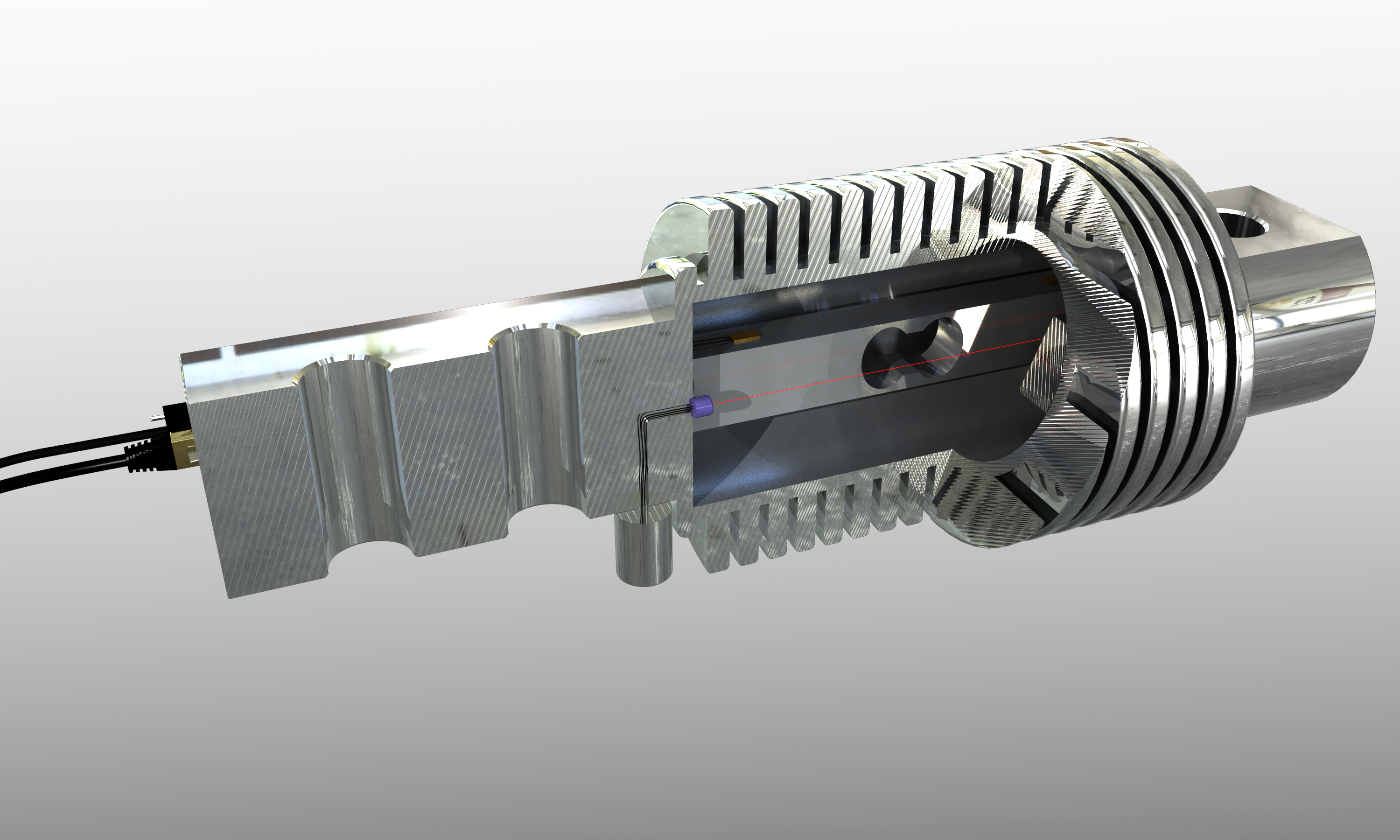

AAA is bringing its deep know-how on ultrasonics by designing and manufacturing the ultrasonic tooling.

AAA is doing the machine modification to integrate the ultrasonic process to the existing laser welding step.

AAA is providing the testing environment.

MPS Micro Precision Systems AG

MPS Micro Prescision Systems AG is driving the usability of the proof of concept by giving the specifications on mechanical strength and hermeticity to be achieved for the applications and/or their premium products.