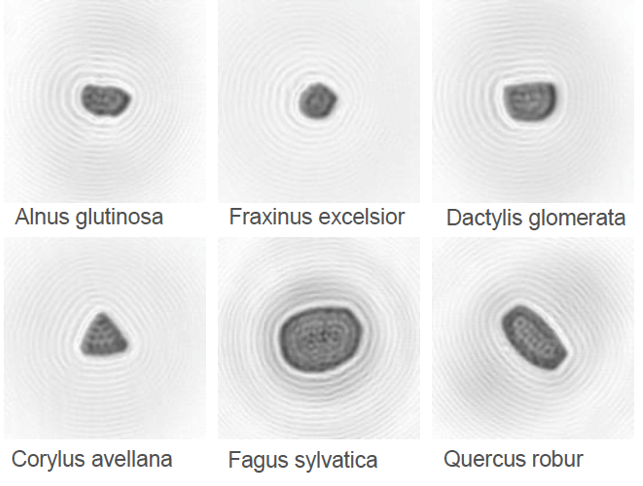

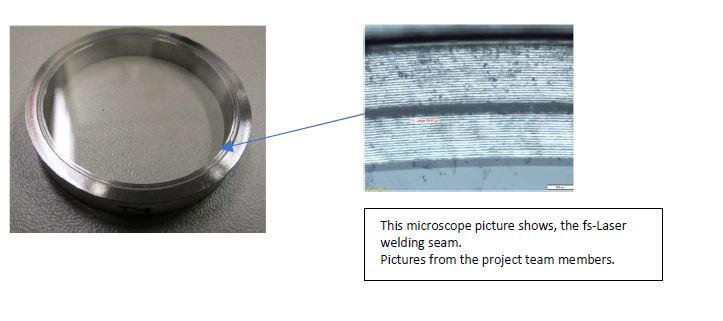

Investigate factors influencing particle formation and finding practical, industrial methods for eliminating the creation of particles during deposition of optical thin film coatings. Developing robust, easy-to-use, cost effective in-process diagnostic tools and/or software for monitoring the coating processes.

Project Partners:

Consortium with 7 industry partners (Bühler, Evatec, Fisba, Materion Balzers Optics, Opcos, Schott, Swissoptic) and 4 research partners (UniNE, BFH, OST, RhySearch)

Bühler AG offers precision optics solutions for a wide range of applications. The company has extensive project relevant experience in the manufacture of large optical coating deposition systems with vast know-how in vacuum components, process control and material characterization. They will mainly participate as exchange partner and observer and in the project, assessing the future applicability of the open innovation developments for their internal R&D purposes.

Evatec is a one of the leading companies worldwide manufacturing thin film deposition systems for the business segments optics, optoelectronic, semiconductor and packaging. For these diverse applications, the company offers various tool platforms using evaporation and magnetron sputter deposition equipped with comprehensive in-situ process control. For all of the applications a low particle level is mandatory. Apart from the open innovation aspect of this project, Evatec will make use of the developed in-situ particle measurement procedures and available ex-situ analytics to improve their coating systems and processes on a bilateral basis.

FISBA AG manufactures optical systems and components and develops of optical systems. The product spectrum ranges from complex optical systems to laser modules, micro-optics and innovative optical components. Project relevant competencies include the layout, design, production and qualification of coatings including surface preparation. Apart from the open innovation aspect of this project, they will perform proprietary process developments using the developed procedure and research partners’ infrastructure. FISBA will make a Dioptic Argus 2.0 ex-situ scanning measurement system available to the project. The instrument can be used by the research-partners for comparison with in-situ and other ex-situ measurement systems and allow for benchmarking and comparison of ex-situ and in-situ results. This will remain the property of FISBA and be returned to FISBA after project completion, or earlier if the device is not usable for the project.

Optics Balzers AG develops and produces coated optical components and sub-assemblies and is a leader in the field of manufacturing low-defect optical coatings. They are consequently ideally suited to assess the limits of the developments within this project, and will make use of the available ex-situ and in-situ analytics for bilateral test and process developments.

OPCOS AG is a newly founded optical coating manufacturer, offering single source support with the selection and specification of suitable optical coatings, through calculation and process development for cleaning and coating, including the corresponding mechanical design and manufacture of auxiliary equipment, through to characterization and documentation of the coatings. They will benefit from the open innovation within the consortium and perform proprietary tests as required.

SCHOTT Suisse AG has extensive experience in manufacturing optical substrates as well as the layout, design and manufacture of coatings. In Yverdon the company produces optical components and coats them using various processes. They will mainly make use of the open innovation results gained from this project.

SwissOptic AG develops and manufactures a wide range of coated precision optical components, assemblies and systems. Along the entire process chain, they are a competent partner from design to series production. The competencies and infrastructure for this project include optical component design, design of coatings and the manufacturing and characterization of coatings, cleaning facilities and environmental test equipment. Apart from the know-how gained from the project, they will perform proprietary developments and make use of the available ex-situ analytics to improve their coating systems and processes on a bilateral basis.

All partners have indicated that they welcome the opportunity to discuss with peers, encourage mutual growth and find synergies within the Swiss optics community.

The four research partners (RPs) bring a very broad variety of competences and infrastructure and very extensive experience in successfully setting up, leading and implementing Innosuisse projects, making the project set-up very strong.

RhySearch Optical Coating and the Time and Frequency Laboratory at UniNE have extensive experience in the design and deposition of optical coatings using IBS, in software and measurement procedure development and coating characterization. Additionally, the IMP at OST and the Institute ALPS at BFH have broad complimentary know-how in laser-based measurement procedure development and additional deposition systems (MS, E-beam). A high-resolution particle measurement device is also available at IMP. Through the combination of the digitalisation experience at RhySearch and the FH OST the first steps to developing intelligent analysis methods on scanning particle measurements can be taken. Confidentiality and creating adequate room for bilateral investigations are crucial for the success of a consortium project. RhySearch has several years of experience in leading complex projects (46850.1 IP-ENG (6 IPs); 26200.1 PFNM-NM (9 IPs); 16871.1 PFNM-NM (9 IPs)). They have an extensive range of measurement and coating services and the developed procedures will be available as a measurement service after project completion.